Winter 2021

Super high density almond orchards in California

Agriculture is changing quickly, and the orchard of the future is taking shape. Stricter regulation, consumer demand, climate change and environmental health are helping to guide agricultural trends. And where there are new trends, growers are left to make some new decisions about how they farm.

Super high density (SHD) orchards are quickly becoming another option for tree nut growers. Already a successful option in apples, cherries, and olives, SHD tree nut orchards are gaining traction in California’s almond industry, with the pistachio and walnut industries following closely.

Leading the SHD movement is Spain-headquartered Agromillora. This high density training system was originally developed in Spain for olive production, and has been finely tuned over the last 25 years. The concept moved from olives to almonds about nine years ago, where it was developed for use in orchards in Spain, Italy and Portugal. Australia, North Africa, and the U.S. have since joined that list, contributing to what is quickly approaching 15,000 acres (and growing) across five continents.

What does this mean for California almonds? For the small trials that took place over the last several years in a roughly cumulative 170 acres, it shows trial and error has paid off. For the 700 acres currently being planted in Arvin, California, and the additional 800 that are scheduled for the remainder of 2021, it means the next wave in almond farming is just beginning.

What makes it different

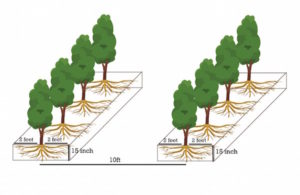

Instead of larger trees at around 132 trees per acre, super high density orchards are planted at 1,089 trees per acre. Done at 10-foot row spacing and 4-foot tree spacing, the trees become more like hedges, with a canopy height of about 9 feet and width of 3 feet. This spacing maximizes light and is designed for precision practices.

“It’s really the only serious way to grow almonds anymore,” said Cliff Beumel, president of Agromillora California, located in Gridley, California.

Agromillora uses the self-fertile Shasta variety, owned and patented by Burchell Nursery, on its proprietary rootstock Rootpac-20, a dwarfing and precocious rootstock that’s also very adaptable and tough. It’s salt tolerant, disease resistant and was selected and bred to have a very compact root system.

The orchard design is geared toward mechanization. Pruning is done quickly and mechanically, and without expensive labor. Tree size means nuts can be harvested straight from the tree with over-row harvesters, without the nuts ever having to touch the ground, let alone lay on the orchard floor for days to dry. This also means little to no harvest dust.

Although the trees cost less because of their size, the initial capital and establishment costs for SHD orchards is higher than a standard orchard, as is often the case with intensive systems. At a cost of over $11,000 an acre, according to Beumel, the return on investment, however, comes sooner because operating costs are lower, and growers are getting bigger crops sooner because of the system’s intensity.

The water question

For growers looking to put in SHD almonds, most of the decisions and logistics of a new planting happen the same as a standard orchard. The major question, however, is about water, especially with California’s Sustainable Groundwater Act (SGMA) looming on the horizon.

“SGMA is coming, and (growers) have to make smart moves based on all the possibilities of what happens,” said Beumel. “We’re trying to anticipate the problems in the future.”

Based on 15 years of experience in fields in Spain, irrigation in SHD fields is designed to be applied very specifically in a very small root zone for a short period of time to prevent, if not eliminate, water waste. This also applies to other inputs. With double line drip and a root system that stays within the top 18 inches and is only 4 feet wide, irrigation will be often, maybe even everyday, but for short periods of time.

“You’re not irrigating for 24 hours once a week. You’re irrigating for what the tree and soil need to precision. The entire system is built around only delivering the amount of water and fertilizer required for the ultimate performance of the hedge in that line, and nothing more,” said Beumel.

The shallow root system is purposeful – even in the high heat of summer in the southern San Joaquin Valley, the trees’ roots don’t need to search for and mine the stored water out of the soil. And Beumel is okay with that. There’s a lot of waste in that water, he said, and the standard almond tree doesn’t use a lot of the water actually applied.

“It’s old ag,” he said.

For growers who may face the fallowing of their land in the wake of SGMA, super high density could potentially change the numbers. A grower who farms 6,000 acres of almonds in a standard orchard may consider fallowing half that acreage because of limited water availability, but each tree in production still requires its original amount of water. According to Beumel, with a super high density orchard that has high efficiency of water, growers could bump that farmable acreage up to 4,000 acres – and use less water.

“The math starts changing,” said Beumel. “It’s on the scale of, ‘What can I do with the resources I have, given the future environment?’”

Although there’s no exact water savings recorded specifically for California yet since the first planting is brand new, Agromillora anticipates – and is excited to prove – about one acre foot less of water than a standard orchard on the same site, based on international results. That’s the best data the company is willing to extrapolate from Spain or elsewhere, given that varieties, farming practices and soil conditions vary.

Data from California fields is part of a much larger picture and purpose for Agromillora. The company partnered with Bronco Wine Co., and together they share the goal of wanting to help change the industry.

“We’re going to track data, and there’s going to be absolute transparency,” said Beumel. “We want the (university and Almond Board) researchers in there. And all the data we get, we’re going to share.”

How the future looks

There’s no doubt that farming is changing, and a lot of the systems that gave almonds the run up to its heyday aren’t sustainable. The significant move to mechanization and efficiency is making companies – and growers – up their game in order to have the value proposition necessary to remain relevant.

It’s inevitable that changing trends, regulation, prices and a host of other factors are altering the grower landscape – some growers are changing their farming practices and business models, and others are on either end of industry consolidation. How this looks for a small, family almond farmer is questionable, especially against a trend of investment firms taking a keen eye to agriculture and the companies that are leading the industry.

Aside from the efficiency and sustainability of super high density planting, this technique opens much wider the door for organically grown California almonds, especially since SHD orchards are harvested at hull split and dried in driers so that the nuts never touch the ground.

“We see at least for the next 20-30 years, the premium on organic almonds should stay pretty strong,” said Beumel. He compared it to the strong conventional-to-organic shift in apples. “I think that’s coming for almonds.”

Organic California almonds are not commonplace, and with strong almond prices, organic crops were not at the forefront for growers other than those who had reasons beyond increased premiums.

“Growers can say they don’t really want to go down that road because organic is hard, but if they plant this system, at least they know that option is in their back pocket. It’s another mitigation factor. Maybe they say they hope they’ll never have to go organic, but if they do, at least this system makes the transition a lot easier than a standard orchard,” said Beumel.

In addition to the 700 SHD acres in Arvin, Agromillora has slated for 2021 about 320 acres in Denair and 315 acres in Ceres.