Winter 2021

Understanding the principles of irrigation efficiency in pistachio

Pistachio lives in a dichotomy: it is drought tolerant, yet can use upwards of 40 inches of water in a season. It is, however, susceptible to stress caused by over-irrigation. With all the current research and technology, truly optimizing irrigation comes with a myriad of benefits, and the more monitored and precise – and the healthier the soils – the more efficient irrigation can be.

But unless growers are designing their systems well and diligently maintaining them, how efficient a system can be is very different from how efficient a system actually is.

But unless growers are designing their systems well and diligently maintaining them, how efficient a system can be is very different from how efficient a system actually is.

Irrigation efficiency vs. application efficiency

It’s fairly common knowledge among growers that just because the water went on, it doesn’t mean the tree actually used it – whether in transpiration or other beneficial use. In fact, there are lots of opportunities for water to escape or go to waste, such as in broken or leaking pipes or canals, evaporation or over-running irrigation, or in necessary cases of pipe flushing and maintenance. There are also often instances where parts of the field are being properly irrigated, while other areas in the same field are being over- or under-irrigated.

Lost water is a hit to the bottom line. Improving irrigation efficiency (IE) is a continuous journey, not only to maintain compliance with regulations, but to be a steward of the agriculture environment, mitigate the costs of water and energy, and to improve farming practices while maintaining high yields.

There’s a significant difference between application efficiency and irrigation efficiency, with the former being event-based and the latter being seasonal. Application efficiency is determined by how much water is stored in the tree’s root zone when compared to how much water was applied in a single application. For example, schedules may be miscalculated, resulting in poor application efficiency until the schedule is properly calculated. Or, in the case of a broken pipe, application efficiency could be very low one day, but high once the repairs are made. Despite these less-than-favorable outcomes for specific events, the overall irrigation efficiency for the season may appear good.

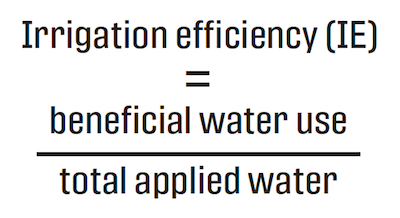

Irrigation efficiency, on the other hand, looks at the entire irrigation season. It’s calculated as the beneficial water use divided by the total applied water.

Beneficial water use appears in a few different forms, including transpiration, where it’s important to match the tree as closely as possible. It’s also seen in the application of inputs, canopy cooling, frost protection and the leaching of salts.

Calculating applied water

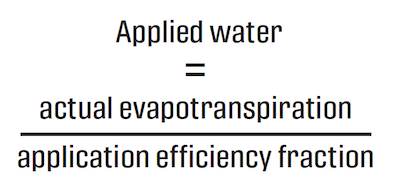

Each system – drip, sprinkler, or otherwise– has an application efficiency fraction, since no system is 100% efficient. Assuming such efficiency rates could actually result in an orchard being underwatered.

For example, if pistachio requires 40 inches of water in a season, and the micro sprinklers in a field have a 0.80 application efficiency, it would actually take 50 inches of water to meet the 40-inch requirement for the season.

40/0.80 = 50 = applied water

Growers also must consider soil types, as the maximum infiltration rates vary among different types and textures of soil. While growers have to match the transpiration of the tree, they also have to match the infiltration rate of the soil and account for any slopes or other factors. Even if the right amount of water is applied, applying it too quickly can result in loss, so having an application rate that is lower or equal to the soil intake rate is ideal.

Distribution uniformity

A uniform distribution allows the grower more control over the field and the inputs that are applied. Irrigation technology continues to provide promising offerings both in data collection and control, but underlying it all is the simple, yet not necessarily easy to achieve, concept of distribution uniformity.

“There’s no point in more technologically advanced precision irrigation management if growers are not evaluating and maintaining distribution uniformity,” said Mallika Nocco, University of California (UC) Cooperative Extension specialist and director of the Conservation Irrigation Lab located at UC Davis.

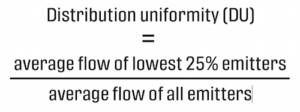

Calculating distribution uniformity involves some in-field work, and growers can do it themselves or contract it out. The flow of the emitters is measured, and distribution uniformity is calculated by the average flow of the lowest 25% emitters divided by the average flow of all the emitters.

For example, a grower has 16 emitters, and the lowest four of them have an average flow of 0.87 gallons per hour (gph). The average flow of all the emitters combined measures 0.97gph. By using the DU equation, this grower has a 90% distribution uniformity. If the average flow of those same bottom 25% dropped to 0.67gph, with the same 0.97gph field average, this would result in closer to a 70% distribution uniformity – cause for concern since there would be trees in the field being vastly underwatered, others probably overwatered, and could be the result of unequal drainage, spacing, pressure or clogs and breakage.

“Similarly, fertigation protocols would be compromised with some trees receiving too much nitrogen and others not enough – poor distribution uniformity means that both the water and everything in it is not being applied in the way you intend it to be,” said Nocco.

This concept helps to ensure growers have an even application season across the orchard. And while maintaining distribution uniformity is a necessary step, it does not guarantee high irrigation efficiency.

“High irrigation efficiency comes from a combination of high distribution uniformity and consistently meeting crop water demand in the root zone,” said Nocco.

Where there is poor distribution uniformity and poor irrigation efficiency, a lot of water is being applied, but not much of it is being used properly by the trees. There may be a blockage or breakage somewhere in the system, but in any case, some trees are getting more water than they should, others not enough, and it’s very inconsistent across the field and across the season as a whole. Orchards that experience subpar performance in distribution uniformity are unlikely to achieve high irrigation efficiency, as the calculations just don’t work.

There can also be instances of good distribution uniformity and poor irrigation efficiency. For example, if the distribution is even across the field, but there is far too much water put on, that water will fall below the root zone and the tree won’t be able to pull it from the soil. For a single application event, this may be no big deal. If overirrigation becomes a habit, it will result in poor irrigation efficiency.

Ideally, growers have everything calibrated, maintained and scheduled so that a field receives good distribution uniformity and good irrigation efficiency. The water is applied to the root zone, losses are minimized, and the trees receive the proper amount at the proper time. It’s no small feat, but essential to the bottom line.

Reaching a DU/IE goal

In addition to scheduling, optimizing irrigation efficiency comes down to the most fundamental components of system design, installation, maintenance and evaluation. Careful consideration of each of these can yield great benefits, but aren’t without their costs, which requires a balance that works for growers and their teams.

There are several ways for growers to tackle this, especially in taking the concept of micro irrigation and putting it into practice. Whether it be with microsprinkers, surface or subsurface drip, having maximum control over the system and timing and amount of applied water helps ensure application uniformity.

With any system, the pros and cons need to be measured against one another. Fields that use a microsprinker and fanjet combination can take advantage of the larger wetting zone, easier maintenance and higher application rates, but would have to justify the higher cost, evaporative or wind losses and contend with additional weed growth. Drip irrigation, on the other hand, is also easily maintained and can limit weed growth and be more financially economical, but is susceptible to clogging and offers a much smaller wetting zone. Then, there’s subsurface drip, which runs the gamut of pros and cons – from minimizing soil evaporation, weed growth and being protected from above-ground damage, to being susceptible to root intrusion and much tougher to inspect, which is only amplified by perennial crops.

Evaluate system function

Irrigation systems experience wear from use, and distribution uniformity decreases over time because of it. Having routine professional system evaluations every two to three years, along with regularly fixing any breakages, flushing and cleaning hoses, and checking pressure and flow rates, can assure that systems are functioning optimally.