Aug 11, 2023UC Davis studies removing rancidification to boost English walnut consumption

A study by UC Davis researchers has examined how shelled walnuts can be improved to foster increasing consumption.

Because of the vast information on health benefits and the urbanization impact changes in eating habits, the demand for ready-to-use shelled walnuts as a convenient, healthy, and nutritious snack food is increasing all over the world.

However, shelled nuts sold as halves or pieces in “ready-to-use” small packages are more susceptible to pellicle darkening and rancidity than their in-shell equivalents. Currently, about two-thirds of the USA crop is exported, and 66% of these exports are sold as shelled ready to use, and its demand is increasing, according to the researchers.

Yet, this package style is generating quality challenges due to the darkening and rancidification of the kernel pellicle.

The application of the cold chain principle and/or low oxygen technology is unpractical for large cropping systems. Thus, a useful quality control system to rank the lots based on their potential visual and sensory quality is important. Then, the lots can be selected based on their potential quality, match market destinations, and are subjected to proper postharvest technologies.

The concern follows increasing world walnut production. China is a leader (50%), followed by the U.S. (25%), with Iran, Turkey, Mexico, Ukraine, Chile, Uzbekistan, and France accounting for the balance. The U.S. is the second-largest producer of English walnuts worldwide, generating $1 billion annually and producing 750,000 tons in 2023.

However, the USA is the top shelled and in-shell kernel export country in dollar revenue. About 99% of English walnuts grown in the U.S. are grown in California. Currently, about one-third of the crop is sold domestically and the rest to export markets (Canada, Germany, India, Italy, Japan, South Korea, Spain, Israel, Turkey, Australia, UAE/Middle East, and the United Kingdom). There is an increase in demand, as two-thirds of exports are sold as shelled ‘ready to use’, but this package style is generating quality challenges, according to the researchers.

Storing and marketing dried and ‘ready-to-use’ shelled kernels in halves and/or pieces that satisfy the current increasing consumers’ demands create new challenges to maintain their visual and sensory quality. To maintain their visual and sensory kernel quality and maximize their postharvest life, kernels should be stored at low temperatures during all steps in postharvest handling.

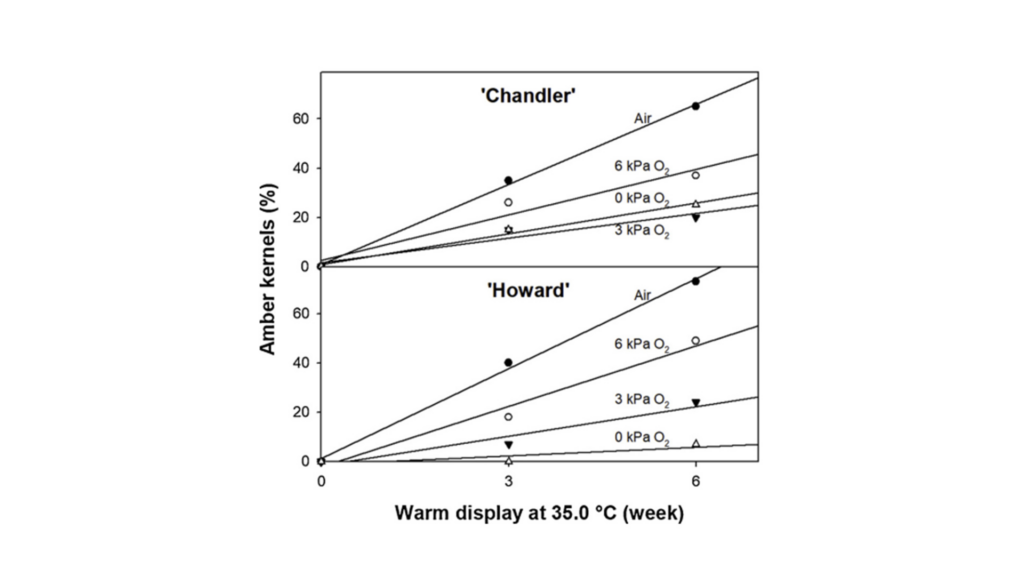

and ‘Howard’ walnut kernels subjected to a harsh (commercial damage) shelling operation and stored for zero, three, or six weeks at 95 degree Fahrenheit and 50% relative humidity at room temperature or a controlled atmosphere containing 0, 3, or 6 (kPa or kilopascal) oxygen.

The cold chain concept includes all steps after harvesting, including hulling delays, storage, transportation, distribution, store retail handling, and home storage. This concept is even more critical when kernels are marketed in small packages and stored for long periods or transported to long-distance markets. When well-handled kernels are stored under proper environmental conditions and darkness, the postharvest kernel sensory quality can be maintained for over a year with minimal quality loss.

Shelling operations induce physical injury to the pellicle that accelerates kernel rancidity and darkening problems; thus, this damage should be assessed for each operation cultivar, machinery type, and speed of processing against the amount of damage, according to the researchers.

The benefits of low-oxygen packaging (MAP) storage on delaying kernel darkening and rancidity, especially after shelling, have been demonstrated to improve their eating quality, delay rancidity, and kernel darkening, according to the researchers.

Application of the ‘cold chain’ principle and/or low-oxygen technology is unworkable for 750,000 tons. Thus, a useful quality control system to rank lots based on their potential visual and sensory quality is important. Then, lots can be selected based on their potential quality and match market destinations, according to the researchers.

The study is published in Horticulturae is an international, peer-reviewed, open access journal published by MDPI. The Spanish Society of Horticultural Sciences (SECH) is affiliated with Horticulturae.

UC Davis’ Carlos Crisosto and Bruce D. Lampinen, of the Department of Plant Sciences, Irwin Donis-Gonzalez of the Department of Biological and Agricultural Engineering, and Selina Wang, Department of Food Science and Technology, are the study’s researchers.