July/August 2025

Advances push tree nut harvesting into the future

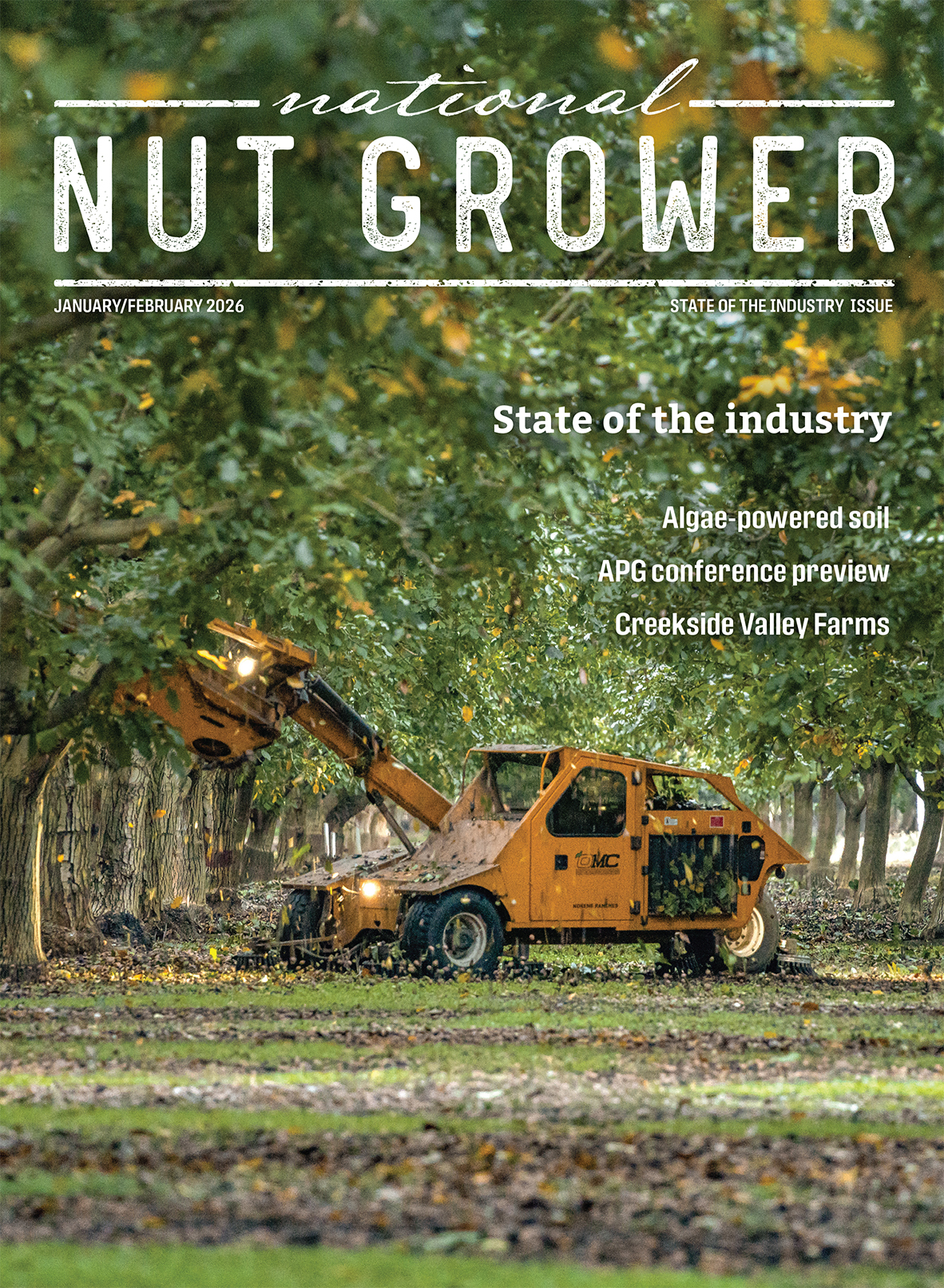

Tree nut producers are no strangers to mechanization. In almonds, pistachios and walnuts, mechanical shakers and sweepers have been essential to harvest for decades. But as the industry looks ahead, researchers are developing a new generation of technologies designed to make harvesting not only faster but smarter.

A recent global review of automatic fruit picking systems, published in the journal Artificial Intelligence Review, outlines how mechanical engineering and machine vision advances are being combined to tackle the toughest harvest challenges. While much of the early focus has been on fruit crops, the technologies being tested have potential for nut growers facing labor shortages, orchard floor challenges and the need for damage-free harvesting.

Calibrated shaking for cleaner harvests

Traditional vibratory shakers, which grip the trunk or scaffold limbs to shake nuts loose, remain the main harvest method for many tree nut crops. But they’re not always ideal, especially for younger orchards or varieties with weaker branch structure, where overly aggressive shaking can cause damage.

According to the study, recent advances in vibratory technology have focused on fine-tuning the frequency and amplitude of shaking to improve efficiency and reduce crop loss. In one example, a crankshaft vibratory harvesting unit paired with a flexible clamping mechanism reached a 93% harvest rate with just 4.6% nut damage, which is significantly better than many existing commercial units. Researchers emphasized that the integration of flexible clamping mechanisms and buffer systems further reduces shock to the tree.

These findings align with the growing demand for gentle, targeted harvesting in pistachios and hazelnuts, where kernel quality and shell integrity can impact marketability. As the study suggests, incorporating feedback-controlled vibration systems could allow future shakers to adapt to different tree sizes and nut loads in real time.

Drones and high-reach devices

For crops like pecans, which are often grown on tall trees with uneven ground, conventional harvest equipment can struggle to efficiently reach high branches. The study notes that researchers are exploring aerial solutions like drone-mounted picking systems as a way to overcome these limitations.

In one example highlighted in the review, a company in Israel developed a drone-based harvester equipped with robotic arms. Tests showed more that 90% picking accuracy for ripe fruit, with the added benefit of targeting only harvest-ready fruit. While this technology is still developing, researchers suggest that it could be adapted to access hard-to-reach areas in pecan or walnut trees, helping reduce losses and labor needs.

Smarter eyes in the orchard

One of the most promising technologies for the future of nut harvesting is machine vision. The study details how these systems use cameras and AI to detect, classify and localize fruit or nuts on trees.

In nut crops, this means future systems may be able to detect hull split in almonds, assess pistachio maturity or even estimate walnut yields based on field imaging. Researchers cited multiple projects where deep learning algorithms allowed robotic harvesters to identify and locate target fruit with impressive accuracy, even when the fruit was partially obscured by leaves or nearby branches.

In one research example highlighted in the review, vision-guided harvesting robots achieved picking rates of 80% to 95% with minimal damage, though these tests were conducted in controlled environments. Still, the trend is clear: As camera technology improves and training data expands, tree nut growers could soon see semi-autonomous equipment that visually targets harvestable products with greater precision than ever before.

Realistic roadmap, promising future

Despite their promise, the study notes that fully autonomous nut harvesters are not ready to replace existing machinery just yet. Field conditions, lighting variability and the rugged environment of many orchards create challenges. Even the most advanced machine vision systems can struggle with obstructed or clustered nuts, which are common in pistachio and hazelnut trees, leading to missed picks or unnecessary damage.

Cost is another hurdle. Many systems highlighted in the study are still in the prototype phase, and researchers acknowledge that the high initial investment may not be possible for some growers. However, hybrid systems, such as retrofitting existing harvesters with vision systems or using robotic arms for supplemental nut collection, can be a practical starting point.

Still, the benefits are hard to ignore. In the face of ongoing labor shortages, environmental challenges and increasing demands for food quality and safety, automation offers a path toward greater consistency and control.

Looking ahead

For tree nut growers, the future of harvest is likely to be hybrid: smart, sensor-driven systems working alongside traditional machinery to improve speed, accuracy and sustainability.

While no single tool will solve every harvest challenge, the research is clear — tree nut growers stand to benefit from adopting tools that increase harvest precision, reduce dependence on labor and support higher product quality.