Fall 2021

Tinkering with the variables

Navel orangeworm (NOW) has been a veritable adversary for California tree nut growers for decades. It inevitably launched an industry whose goal is to beat it by improving treatments and technologies, and sterile insect technique (SIT) is picking up steam as the next addition to a suite of navel orangeworm control options.

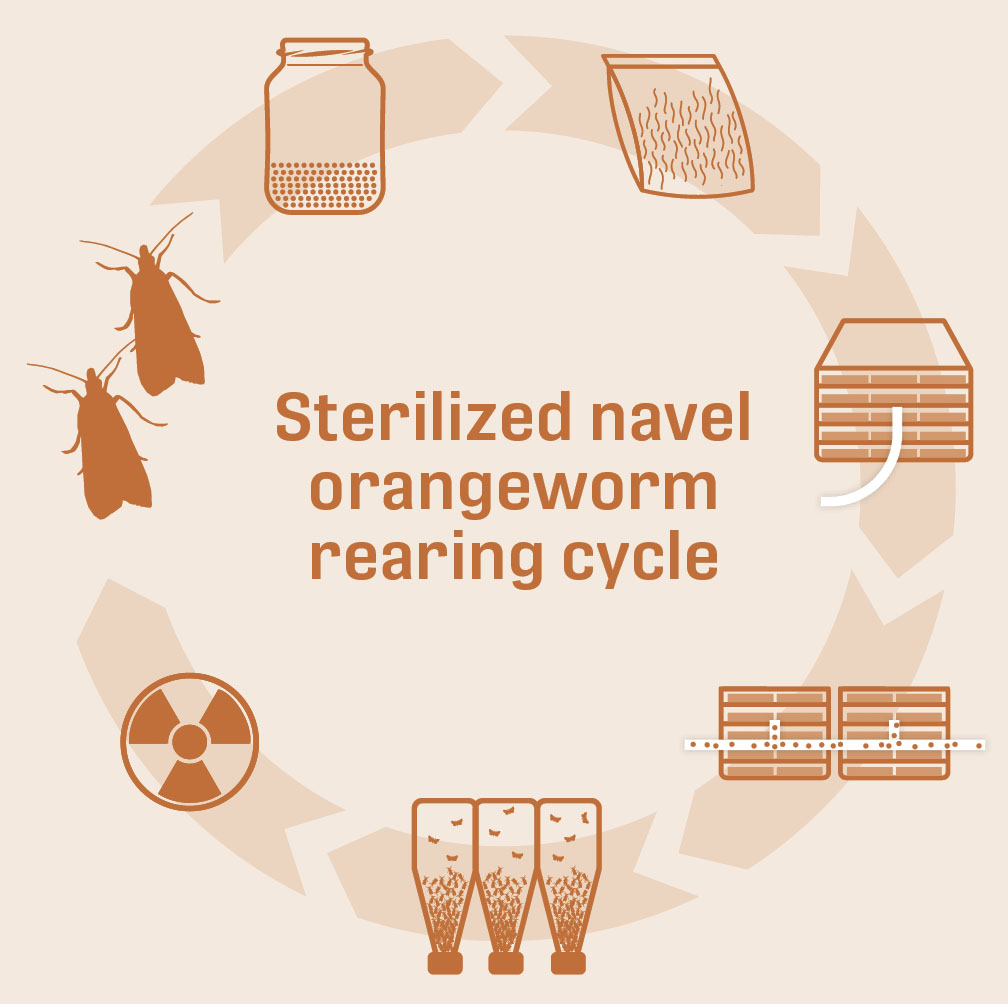

SIT is simple in concept: mass rear large numbers of the pest insect, sterilize them, release them into the field so they’ll mate with wild insects and render their reproductivity to nil.

Sterilizing insects, generally speaking, isn’t a new concept. Using radiation to sterilize insects was just one of the many novel ideas people experimented with as they dabbled in and toyed with radiation in the beginning of the 20th century.

The success of a 1950s program against new world screwworm in the U.S. and Central America was so successful that it paved the way for more SIT programs, most of which targeted flies, moths and beetles since these insects are more easily mass reared in a lab.

Today’s use of sterile insect technique for navel orangeworm is a pick up from where University of California (UC), Berkeley, first started with irradiation of navel orangeworm in the 1960s. It’s also the next iteration of what was a USDA project to eradicate pink bollworm (PBW), another moth, from U.S. cotton fields. Using a combination of tools, much like how there are multiple options for controlling NOW, pink bollworm was officially eradicated as of 2018.

This also meant the facility in Phoenix, Arizona, that was used to mass rear sterilized pink bollworm moths was now available. Seeing the opportunity for its use in navel orangeworm, the California pistachio industry made the investment to get the project up and running.

“Many cotton growers switched from cotton to pistachios. These growers were familiar with the pink bollworm program and knew the facility was winding down PBW production,” said Bob Klein, manager of the California Pistachio Research Board. “As pistachio growers, they were interested in seeing if we could do for NOW what was done with PBW, and as cotton growers, they wanted to preserve the facility in case PBW came back.”

The California Pistachio Research Board identified a significant need in the industry, and the American Pistachio Growers Association led the efforts in securing federal funding.

The pistachio industry, joined by USDA Animal and Plant Health Inspection Service and Agricultural Research Service (ARS), and the California Department of Food and Agriculture, formed a technical working group that conducted radiation-dose response studies at the Phoenix facility on navel orangeworm, resulting in the first field releases and experiments on sites in California in 2018.

“All of this was underway when I joined Kearney in 2017, and it was one of the first conversations I ever had with the pistachio board,” said Houston Wilson, assistant cooperative Extension specialist in the Department of Entomology at UC Riverside, and one of the lead scientists working on sterile NOW in California today. “The pistachio industry had just made this large investment in the Phoenix facility to start looking at sterile insect technique for NOW, and, as a tree nut entomologist, they were looking for someone to do research on this. It was a really unique opportunity.”

In 2019, the Almond Board of California also joined the effort. The Western Agricultural Processors Association and the Almond Alliance of California are also part of the effort.

Viable moth challenge

The University of California Kearney Agricultural Research and Extension Center in Parlier has one primary similarity to the facility in Arizona: they both rear navel orangeworm in jars. And while the Kearney Ag Center can rear hundreds of moths, the Phoenix facility currently rears over 750,000 navel orangeworm moths per day, with the capacity to mass rear millions.

This, however, could be where the concept’s simplicity ends. Rearing moths and having them behave according to plan are different endeavors. For one, figuring out the best release methods, locations, timings and number of moths to be released are challenges unto themselves.

Verifying if the moths are viable is another matter.

The verification of reared moths is basically determining if they behave the same as wild moths – whether they fly, are attracted to the opposite sex and follow pheromones. Life in a jar is not the same as life in the field, and the effects of mass rearing and transportation can affect moth performance.

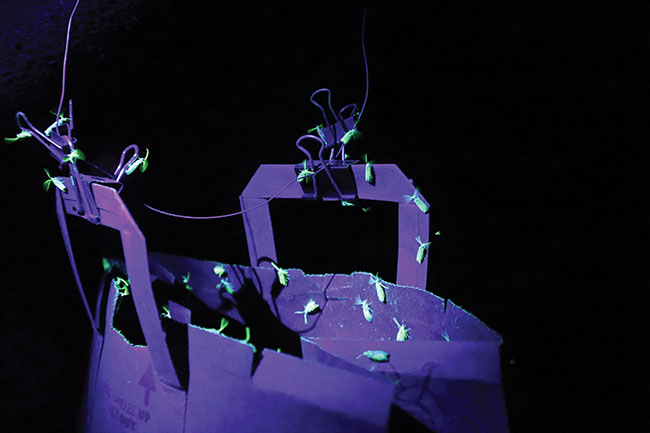

This was seen in the 2018 ground release of sterile NOW, when Wilson and his colleague Chuck Burks, research entomologist with USDA-ARS, were unable to recover hardly any sterile male moths. However, in that same year, sterile females in mating tables – a virgin female moth placed in a cup and exposed overnight – were able to attract wild male moths. So while the sterile males appeared to disperse/fly poorly, the sterile females did seem able to attract wild males – a good first step towards SIT for navel orangeworm.

After tinkering with a few variables in 2019, the Wilson/Burks research team found that providing more vertical space for the sterile NOW to rest on during release led to improved dispersal and recovery. Furthermore, improvements to the rearing and transportation system also improved sterile moth dispersal and mating. It was seen as a breakthrough, and resulted in better dispersal and recovery of sterile moths.

Whether there are any negative effects of irradiation still remains unclear, since these potential effects may be masked by larger impacts associated with the rearing and transportation of the sterile moths.

“The technology for SIT has improved a lot over the past few decades. Irradiation is safer, especially if using new tools like x-rays, which makes it a bit more acceptable to the public,” said Wilson. “Whereas, previously, these SIT programs were typically large state-led projects because it was so expensive to get nuclear material to irradiate moths at scale. Today some of these technologies are more readily accessible, which makes SIT a bit more approachable for a commercial entity to develop and implement a program like this, especially if they are working closely with university and USDA researchers.”

Wilson and Burks now have an x-ray irradiator at the Kearney Ag Center and the sterilizing work to be done with it is in the early stages. A study published a few years ago had shown the successful x-ray irradiation of NOW moths, and after repeating the work with the Kearney unit to prove its success, research will look at field performance and quality of the moth with an eye towards an actionable SIT program, although that will likely be some years down the road.

A renaissance era for SIT

It has been a journey to get to a verifiable sterile moth that mates with wild moths, but the larger scale work that dives into the details is just ramping up. With several million dollars invested annually into the Phoenix facility, and high-value crops with a low tolerance for damage still battling a pesky and economically damaging pest, efforts and urgency to finetune SIT are underway.

Overflooding ratio: the optimum ratio of sterile insects to wild insects

Initially, determining the overflooding ratio was off the table with a moth that didn’t fly. That has since changed.

“We know we can put them in the field, we know they fly, and we know they can find wild moths and mate with them,” said Wilson. “While this sterile moth is far from optimized, we’re at least now getting to a point where we can reasonably start to look at what an overflooding ratio might look like.”

This year, Wilson and Burks hope to set up an experiment that pairs orchards with and without the release of sterile moths to see what the impact is on wild NOW fertility under field conditions.

“We want to see if we can observe a change in the net fertility and, potentially, the crop damage in those blocks with and without sterile insect release,” Wilson said.

For now, the comparisons will focus there – fields with and without the release – as the number of moths going out into the field is really a function of how many moths are actually available for the experiment. If there is an effect, the next step would be determining more specifically how many moths are truly needed by comparing fields that have a lot of moths released frequently with those that have a moderate level of moths, and those that have none.

The idea is to narrow in on how many moths are needed per acre, how frequently, and how many are needed in relation to the wild population, which fluctuates over the season.

“The number right now is basically as many moths as we can per acre as frequently as we can per season. That’s just where I’m going to start – using a really high overflooding ratio simply to see if we can get any effect,” said Wilson. “If we can’t get any effect under those extreme conditions, then we’ll need to focus more on further refining the production, transport and release processes, because there are still improvements that need to be made in those areas.”

Wilson likens this era as a renaissance for sterile insect technique, given the availability and affordability of so much new technology to support these types of programs. It’s a non-chemical strategy, which makes it appealing to growers and industry looking to reduce the environmental footprint of crop production. At this point, this SIT program isn’t looking to eradicate NOW, but rather to be added as an available tool and/or service that complements sanitation, well-timed insecticide sprays and mating disruption.

“We’re having a lot of conversations right now about how all those IPM practices fit together,” Wilson said. “Because with mating disruption, you’re trying to keep the moths from finding each other, while with SIT you want the steriles to find the wilds. So, for instance, how do you use those two technologies together? I think there are ways to do this, either separately or together, and we’re just getting started on better characterizing how this would work.”

SIT works best in an island-type setting, where there isn’t much movement of the wild moths nor the sterile ones in and out of the field. And while there are 2 million acres of tree nuts in California, researchers agree that the sterile moths probably aren’t needed on all 2 million acres.

“It will still need to be part of a larger IPM program, but we would like to reduce pesticide use and the pressure on insecticide resistance with a new environmentally benign method,” said Klein. “We are hoping that this approach will provide measurable control of NOW by reducing nut damage.”

But where they are needed is still to be determined. Better understanding the ecology of both the wild and sterile moths will shape the overflooding ratio and the release locations.

“This is why we’re ramping up our efforts, since there are so many moving pieces within this system that need to be better understood,” Wilson said.

Models and maps

This year, the SIT project was funded by the California Pistachio Research Board to do an economic and ecological scenario – essentially, a modeling exercise – that looks at all the orchards in the state and their configurations. Then, by adding data such as NOW’s dispersal capacity, minimum acreage for mating disruption, and some potential overflooding ratios, the team hopes to create a map that shows priority areas that would benefit best from a particular control or mix of controls, such as SIT and/or mating disruption.

It would then be followed up with an economic analysis that incorporates transportation costs, insect release costs and other factors to see if this approach is both ecologically feasible and economically rational.

“It’s a complicated and nuanced technology,” said Wilson. “And it’s a long road to develop SIT, but ultimately this could have some major benefits in the long term to California tree nut growers.”

Overseeing the program is the Navel Orangeworm Action Committee, made up of affected growers and industry groups, and the Navel Orangeworm Technical Committee, made up of scientists working on the project.

There are currently various SIT programs for moths of agricultural concern around the world, such as light brown apple moth in New Zealand, grapevine berry moth in Chile, false codling moth in South Africa, and codling moth in British Columbia and Washington state.

Above photo: One reason for weak dispersal was the pests’ fight for vertical space when introduced into the field.

Photos: Houston Wilson/University of California